To produce hardware like the bitcoin wallet we’re building, we typically work with a contract manufacturer (CM), a business that offers a combination of specialized services required to build, assemble, test, and package consumer electronics like the wallet hardware.

The primary business value of a CM typically stems from their ability to manufacture at high-volume during mass production (MP), and a great CM partner can also bring significant value to the early, iterative stages of development before a product is available to customers. We call this stage new product introduction (NPI) -- and a capable and flexible partner with significant NPI experience can help us bring new products to market quickly, with high quality, and with new, ambitious parameters in our design and scale.

How do we choose the right partner for a function so critical to delivering our product? Read on to learn more about our considerations, our decision, and what’s next.

What We Consider

When evaluating potential partners, we consider a wide variety of factors across engineering, operations, business, and human dimensions – as well as a seemingly infinite list of questions we ask potential CM’s (and ourselves) to inform the evaluation. While there’s no perfect or exhaustive rubric, we consider roughly the following categories:

🛠 Engineering capability: what product design services do they offer across electrical, mechanical, and software domains? What capabilities do they have for validating products on the manufacturing line (e.g. in-house design of the mechanical and electrical test fixtures used to interact with partially-assembled devices)? Which of the CM’s team members would support these engineering activities, where are they located, and what is their ability to support us across time zones and onsite at build activities during development? How does the CM support new product introduction (NPI) versus mass production (MP) across their sites and teams - and will that map well to our product needs? What aspects of our product design are most challenging, and how experienced is the CM in those dimensions? Have they shipped similar products in the past? What reliability testing - the process by which we iteratively improve the robustness of our product by simulating real world and environmental factors - is the CM experienced with, and which tests can they perform onsite versus at a third party location? How deeply - and how quickly - can the CM team analyze and root-cause failures that occur during production?

📊 Operations capability: how does the CM manage the wide variety of materials and suppliers that we need to successfully develop and manufacture consumer electronics? How do they handle a wide range of customs considerations for parts that come from across the globe? Are their processes robust enough to foresee, handle, and correct issues that arise in mass production? Are their processes flexible enough to handle the urgent demands of fast-paced development of a new product category? What experience does the CM have in designing and optimizing for supply chain sustainability and security? What operational security requirements are they capable of supporting? What capabilities does the CM have to pack units out for delivery to customers - potentially in a large swath of region - and product-specific configurations? What direct-to-consumer shipping capabilities do they have in-house or via partner relationships, and how easily can they reach a broad set of international markets?

🔎 Quality: how does the CM ensure the product is built according to the product requirements? How do they inspect the individual components that make up the product, and how do they perform cosmetic inspections to meet physical/industrial design requirements? How do they ensure long term reliability of the product? How do they manage bill of material (BOM) changes, and what processes are put in place to ensure BOM accuracy? How effectively does the CM capture manufacturing line data in order to report on business metrics, quality metrics, and trace issues that occur in the field back to manufacturing process characteristics and time frames?

🤝 Business and leadership alignment: how does our product’s potential fit into the CM’s strategic priorities? What is the CM’s leadership team (and our own) optimizing for over the next 5+ years? Is the CM’s revenue dominated by a small set of existing customers (or even just one of them), and if so, what impact does that have on their ability to support us? How do we jointly align our growth objectives in the short- and long-term?

📈 Capacity for growth: how many units of different product lines does the CM produce each year at the location they’re suggesting for us, and across what types of products? How close to capacity is the CM operating at in the suggested location, and are they able to scale beyond that? How do they allocate capacity amongst different customers? What locations does the CM operate globally, and how do capabilities and cost parameters vary across their global footprint? Could they be a great partner for subsequent product lines we imagine, or other businesses our parent company (Block) operates?

💰 Cost: what non-recurring engineering (NRE) fees should we expect to pay for the services we choose to leverage during development? What per-unit cost should we expect at different volumes of units produced, and how does that map to our business and growth goals? What hidden costs might contribute to the total cost of manufacturing, from equipment purchases to team travel or local hiring required to work effectively across time zones? How willing is the CM to optimize the manufacturing process for cost, continuously identify cost improvement, and pass on cost savings to us? How will they achieve these goals and operate in a lean fashion without sacrificing product quality? What transparency will the CM provide us on cost drivers so that we can work together to minimize the cost?

₿ Cryptocurrency-specific policy risks: what regulations and/or regulatory frameworks are in place or in development that apply to acquiring, holding, using, and developing for cryptocurrency, including bitcoin, and which of those policies matter most to our manufacturing location decision? How likely are these to impact our ability to produce hardware that protects bitcoin, and over what timeframe?

🚧 General policy risks: what regional and local policies could impact our ability to produce hardware, including but not limited to trade restrictions, political conflict, corruption, and pandemic management?

Who We’re Working With - and Why

Once we’ve collected data on the categories above, our next step is to weigh the tradeoffs that come with each possible choice of CM – after all, there is no one perfect supplier. Our goal at this point was to determine which categories we want to prioritize for a given product, our team, and our business at this stage of our journey. Our decision was ultimately guided by the following areas of differentiation:

- Minimizing potential for cryptocurrency-specific policy changes to disrupt development

- Minimizing potential for pandemic-related and other global supply chain and travel restrictions to impact development

- Prioritizing support for early stage development activities, including ability for our engineering team to work closely with the CM team via time zone and physical proximity

- Potential for broader, long-term partnership

With the above factors in mind, we’ve chosen to partner with Flex, a leading contract manufacturer with broad capabilities and a global presence, at their Austin, Texas site. This choice brings Flex’s strong engineering and operational capabilities to our project, reduces the challenges and costs that come with supporting a site on the other side of the world, and helps insulate our manufacturing operations from Bitcoin- and pandemic-related regulatory risk during our critical earliest stage of development. Manufacturing with Flex in Austin will help ensure we deliver a great first product on time - which is exactly what we’re focused on now and excited to accomplish together.

What’s Next

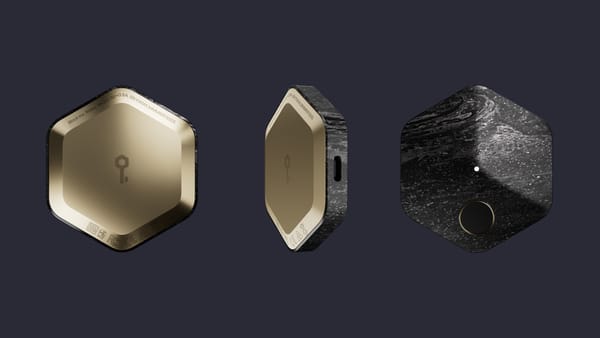

We’ve started to design and build the hardware at Flex’s site in Austin, and you can read more about where we are in the development process (and see photos of the early prototypes!) in our recent post about our iterative design and validation process. We're also establishing our working relationship and processes with the talented team at Flextronics, so that together we can effectively handle all the challenges and risks that come with developing beautiful and robust hardware that delights our customers. Look out for continued updates about our product development, including details of our approach to manufacturing and security, in future posts here on wallet.build. If you have feedback on our development process or to let us know what you want to hear about next please reach out to us at [email protected] or on Twitter.

And if this post and project sounds interesting to you, consider applying for one of our open roles: